Shackle is a U-shaped metal piece secured by a clevis pin or a bolt along with a nut across the opening. The two main parts i.e. body and pin serve major purpose of a shackle and the body can have an anchor or chain shape.

Different types of lifting shackles exist in the market with different features and capabilities to fulfill your needs. This makes them suitable to be used for different applications including rigging and sailing.

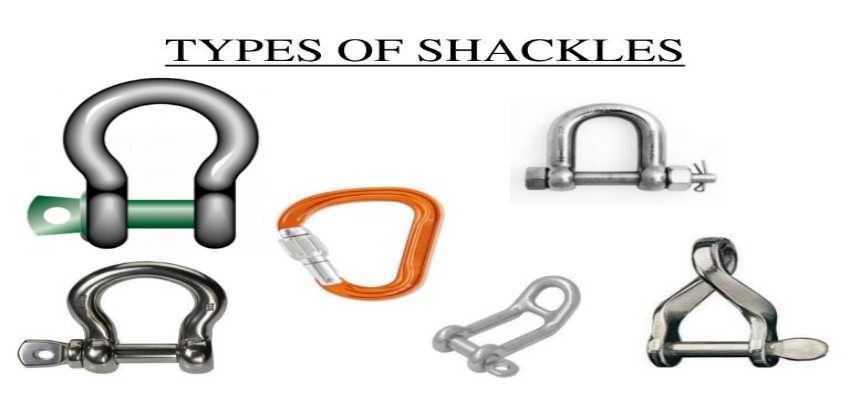

Let’s look at different variations of shackles as per shape and usage-

Bow Shackle and Dee Shackle

D-shackle has a ‘D’ shape design that generally has a pin close. A small loop is made to take heavy loads primarily in line. Similarly, Bow shackle has a round ‘O’ shape design with a more defined bow area. The round design makes it easier to carry loads from several directions and a large loop is capable of handling larger strap.

Stainless Steel and Galvanized Shackles

The galvanized shackles are best meant for industrial applications putting moisture as a less serious issue. They have a thin zinc oxide coating that protects steel from elements producing corrosion and oxidation. It is less expensive than the stainless steel although delivers the equivalent strength and durability.

The stainless steel shackles are well-suited for marine applications including sailing and yacht rigging uses as being corrosive-resistant. The molybdenum composition makes these lifting shackles resistant to ocean water mist or spray, and they work well in high chloride environment.

Green Pin Shackles

These lifting shackles are made of steel and designed to give a better radius to the sling that it lifts and improves its life span. They are used in confined spaces and the high strength material minimize the physical dimensions of a product while maintaining functionality plus working load limit. Green pin shackles can be used in extreme climatic conditions because of its material properties.

Snap Shackles

Snap Shackles are made with a spring-activated mechanism and can be used with single hand. They are perfect for the applications where speed is a dominant factor and there occur instances where continuous connection or disconnection is required. The lower working load limit does not make it suitable for heavy-duty applications.

Closing Words

Let’s look out the different variations of the lifting shackles and pick the most preferred one for your workplace keeping all the specifications in mind. Each of these shackle types are of different capacity and cannot be used in all environments. So, be selective in making a choice that can give you safe results.

Author Bio

This post has been penned down by author who is a trained engineer at Bishop Lifting Services and writer by passion. His writing skills showcase the important traits of lifting shackles and its different versions to make its best use by interested people.