Next time you’re wondering why your new electronic device is malfunctioning, it could have something to do with the improper design of its printed circuit board (PCB). In layman’s terms, this is the part that electronically connects and mechanically supports the different components of the device. However, faulty PCB design might not be the only culprit behind the disruption in performance; electromagnetic interference (EMI), a kind of energy produced by electronic gadgets, also wreaks havoc. So how does this happen? In any type of wireless system, each wire receives and transmits false signals, thereby degrading the overall performance and capacity of your gadget. You might be wondering how best to combat the situation. Well, besides smart PCB design, you’ll require the proper board level shielding solutions to optimize device performance. Such protective shields are carefully constructed to fortify against spurious signals that interfere with the operations of electronics systems, subsequently facilitating optimal performance. Read on to learn more about circuit board level shielding solutions.

Next time you’re wondering why your new electronic device is malfunctioning, it could have something to do with the improper design of its printed circuit board (PCB). In layman’s terms, this is the part that electronically connects and mechanically supports the different components of the device. However, faulty PCB design might not be the only culprit behind the disruption in performance; electromagnetic interference (EMI), a kind of energy produced by electronic gadgets, also wreaks havoc. So how does this happen? In any type of wireless system, each wire receives and transmits false signals, thereby degrading the overall performance and capacity of your gadget. You might be wondering how best to combat the situation. Well, besides smart PCB design, you’ll require the proper board level shielding solutions to optimize device performance. Such protective shields are carefully constructed to fortify against spurious signals that interfere with the operations of electronics systems, subsequently facilitating optimal performance. Read on to learn more about circuit board level shielding solutions.

How Does PCB Design Play a Major Role in EMI Shielding?

The majority of wireless technology used in modern times, such as tablets, laptops, or cell phones handle electromagnetic radiations emitted from two separate sources – the internal digital circuits, and the radio frequency (RF) front end that generates the signal in the first place. Most of the contemporary circuit board designers have to confront the challenges of devising a product that gives off minimal emissions. As soon as they have achieved this, the designers move on to the next phase of the task –shielding the sensitive parts of the device board for the purpose of preventing any radiation from affecting it and to protect the device from exposure to emissions from other parts of the system.

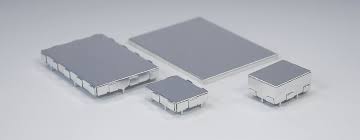

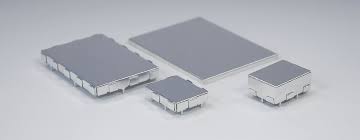

Types of Circuit Board Shielding Available

Circuit board level shielding can be found in lots of different sizes and shapes. They are composed of diverse materials, and this might range from common metals, like tin and stainless steel, to metal films and conductive foams. Circuit board shielding might be available in the form of grounding pads, gaskets, and low DC-resistant shields. Such kinds of innovative, advanced shields remain equipped with electrically conductive interfaces, and are capable of providing maximum shielding effectiveness for a few of the most demanding applications, such as handheld wireless devices, power amplifiers, and wireless base stations. For instance, gaskets composed of metal may often be used for the purpose of imparting effective shielding to a specific enclosure. They are able to create a conductive barrier and assist in the prevention of EMI leaks from the circuit board of a device.

It is for this reason that an EMI shield must ideally be a sealed container that is without any opening. However, this is technically impossible in real life, since the chips that remain present within the container do not have any output and input. Moreover, they remain connected to a power source and the leakage might occur through these openings. Additional measures must be taken for the prevention of such an occurrence.

Which Factors Influence Circuit Board Shielding Abilities?

How effective a particular shielding solution is depends on three diverse properties of the shielding material. These are permeability, thickness, and conductivity. The level of conductivity and permeability of a particular material determines the ability of the solution to transmit or emit EMI signals. Mechanical strength and airflow are two other factors that must be considered during the design process of circuit board shielding solutions. All of the high quality solutions come with holes or apertures in their structures that permit air to flow via the circuit, thereby limiting the amount of thermal buildup that occurs within the circuits. This prevents significant wastage of power.

Circuit board level shielding has a major role to play in the optimization of your electronic gadgets. It is necessary for maintaining the integrity of the devices. Electronics manufacturers must, therefore, be careful when it comes to choosing the proper shielding solution.